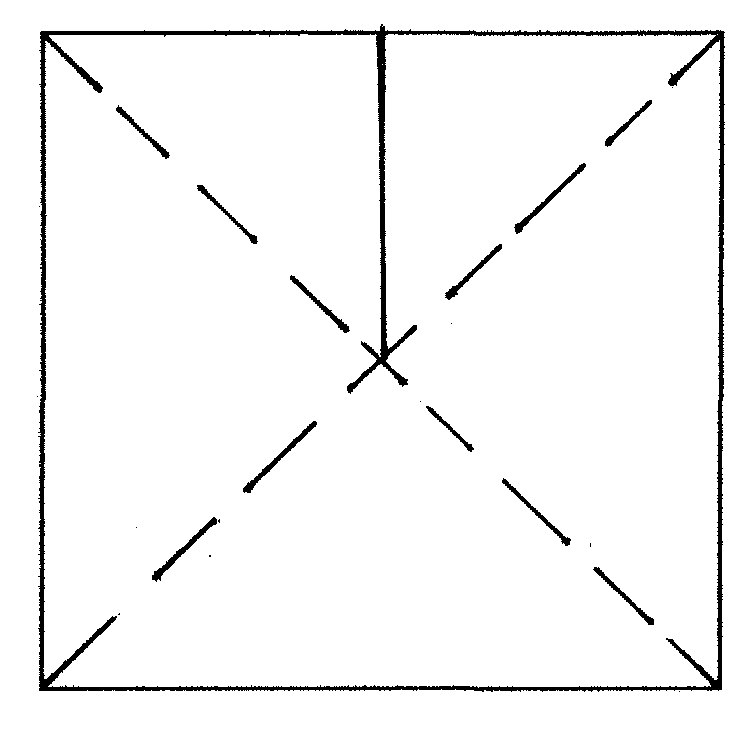

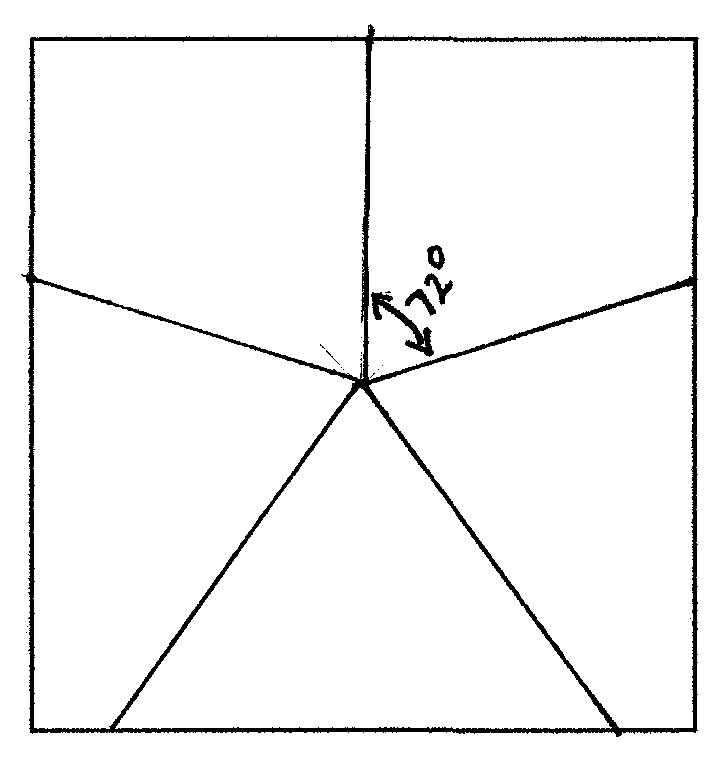

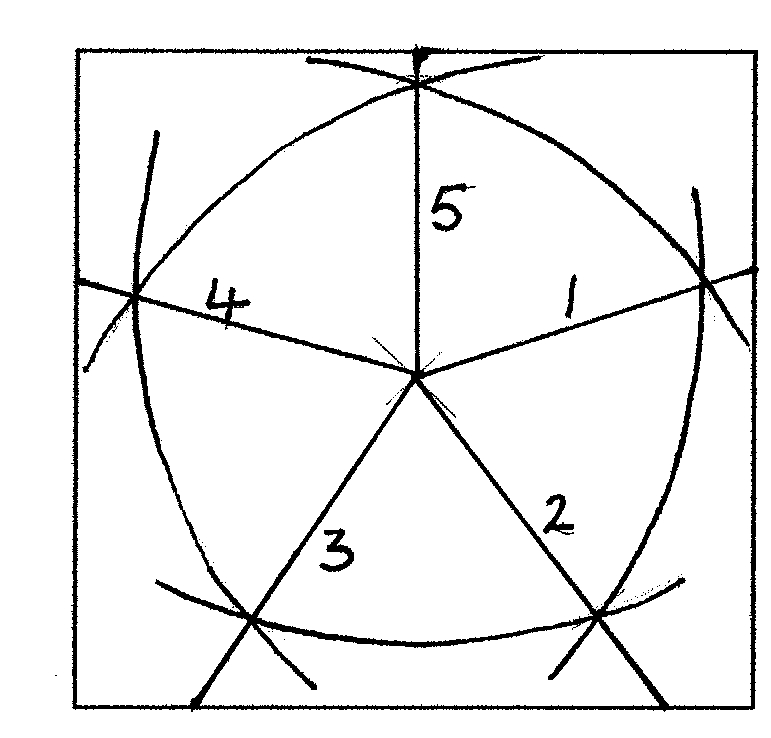

Using a compass on the centre point of the blank, mark a further reference point near to the edge of the blank crossing each of the 72 degree division lines.

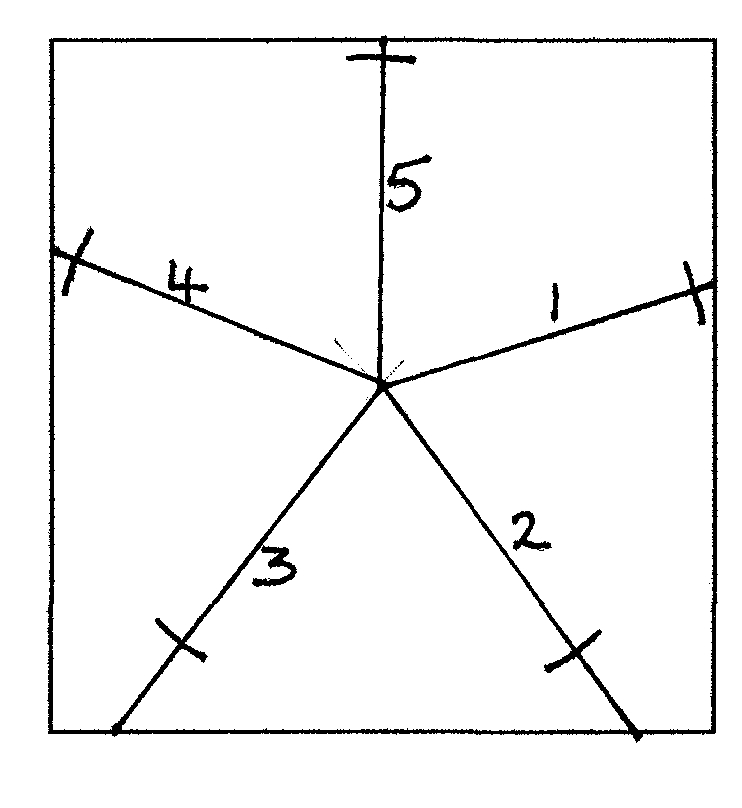

Starting at the first 72 degree line, number each of the division lines 1 to 5, working clockwise around the blank.

Repeat this process on the reverse of the blank, working anti clockwise. The numbers on the obverse and reverse sides should correspond to each other.